Rug-Rel has graphite machining experience over decades. We can machine most graphite component parts in the required shape & dimension at our graphite machining workshop in UK.

The range of graphite specialties is extremely diverse using graphite’s which are isostatically pressed, extruded, die-moulded and vibration-moulded graphite, carbon and graphite felt to carbon fibre-reinforced carbon.

We produce graphite machined parts for following applications:

Graphite for Aerospace Industry.

Graphite for Defence Technology.

Graphite for Aluminium Industry.

Graphite for Electronics.

Graphite for High-Temperature Applications.

Graphite for Industrial Application.

Graphite for Metallurgical Industry.

Graphite for Recreational Products.

High Performance Graphite and Carbon Solutions in Extreme Environments.

Aerospace Industry

The aerospace industry requires severe safety demands with components that are both reliable and resistant to extreme environments. Graphite is in demand for surface tiles on space shuttles, in nuclear technology as a neutron moderator, and under extreme cold conditions such as in cryogenic applications.

Graphite & Carbon uses in Defense Technology.

Defence Technology

Reinforced carbon fibers have already proven their extraordinary properties. Factors such as reduced weight and complex geometrically formed components offer a series of advantages in the areas of protection for

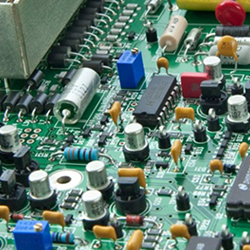

Graphite & Carbon uses in the Electronics Industry.

Electronics Industry

Global computerisation demands ultra-pure forms of graphite for electrical components and circuitry. As automation increases, so will the demand for graphite in electrical systems and circuits.

Graphite & Carbon uses in High Temperature Applications.

High Temperature Applications

High-temperature applications such as the heat treatment of metals under vacuum or hot gas duct components require the use of Graphite and Carbon. Machined to the appropraite shape and size Graphite and Carbon can withstand the demanding high temperatures where other products would fail.

Graphite & Carbon uses in Industrial Applications.

Industrial Applications

Chemically highly corrosion resistant and an excellent conductor of electricity, graphite is an essential component of welding rods, coatings, most high duty refractory bricks and electric arc electrodes.

Graphite & Carbon uses in the Metallurgical Industry.

Metallurgical Industry

Graphite can withstand extreme temperatures, making it perfect for the use in the metal industry in the creation of steel and also in the recycling of aluminium.

Graphite & Carbon uses in Recreational Products.

Recreational Productsy

Graphite is used in furnaces as part of the carbon-fibre creation process from raw materials. Graphite blocks are used within the furnace walls due to their resistance to extremely high temperatures. Both rigid and non rigid carbon and graphite felt are used as insulation in these carbon fibre furnaces.

Because of its energy-absorbing quality, graphite is used to develop high performance sports equipment including

Get in Touch Now

Book a Demo call with our consultant and let us assist you with your requirements.

If you’d like a quote or would like to talk to us, please fill in the form below. Alternatively, you can call us on

+91 80 2955 8280 (IND) or +44 7914 935648 (UK)

All Rights Reserved To Rug-Rel, Bangalore.

Site by Websmartindia